automation stamping welding fixture inkonzo umenzi wenkonzo

Ividiyo

Inkcazo

| Uhlobo lweWelding: | ARC Welding |

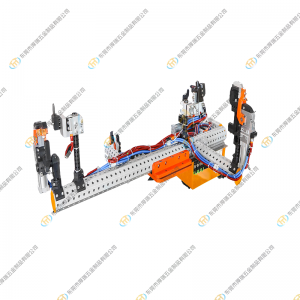

| Ukulungiswa kweWelding: | 6 iiseti |

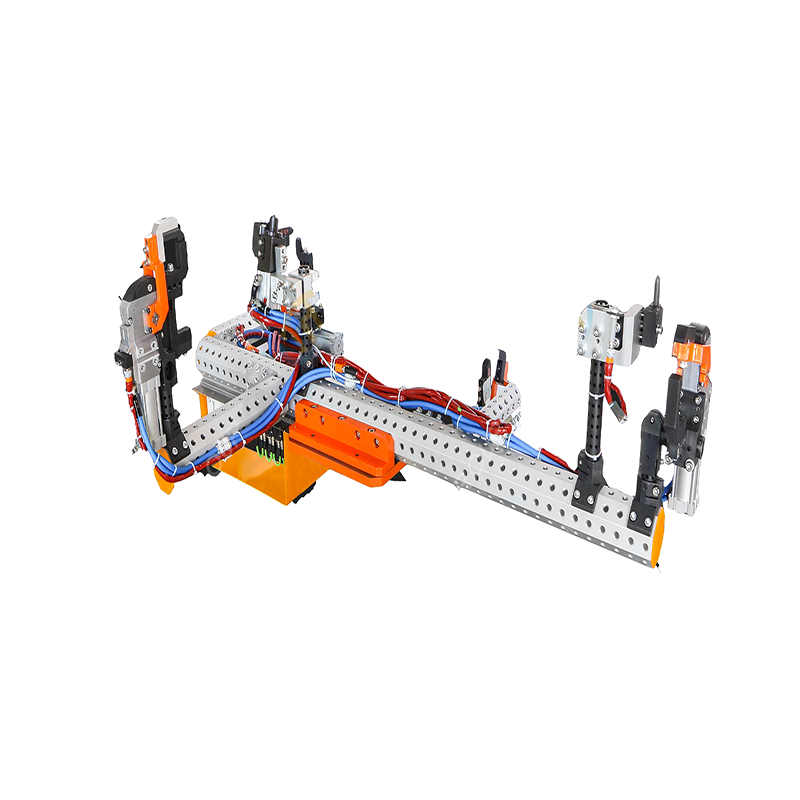

| IiGripers: | 4Iiseti |

| Izinto: | Isinyithi |

| Amazwe athumela ngaphandle: | Khanada |

Iinkcukacha zeMveliso

Intshayelelo eneenkcukacha

Le yibhetshi ye-welding fixture ye-AB Ring, ngokupheleleyo kwiiseti ezili-15, esizenzele umthengi wethu waseCanada.Uluhlu lwemveliso yeWelding, ibhetshi encinci kunye nomjikelo omfutshane zezona mpawu ziphambili kushishino lokuvelisa oomatshini banamhlanje.Ukubonakala kolu phawu kukhuthaza ukudalwa kwengcamango ye-flexible fixture kunye nophuhliso lobuchwepheshe.Njengoko umjikelo wokuhlaziywa kwemveliso usiba mfutshane kwaye umfutshane, indlela yokutshintsha ngokukhawuleza ukusuka kwiimodeli ezindala ukuya kwiimodeli ezintsha kunye nokunciphisa umjikelo weprojekthi lukhokelo lophando lwegugu ngalinye.

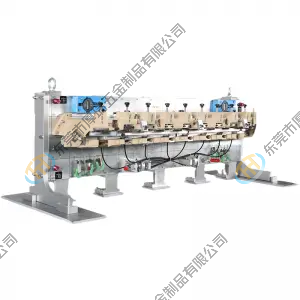

Isixhobo sokuwelda ikakhulu sibandakanya ipleyiti esezantsi, i-clamp ekhethekileyo, isixhobo esincedisayo, inkqubo yokulawula iinxalenye ezininzi.Ipleyiti engezantsi yi-chassis yamacandelo okulungiswa, umpu we-welding ozenzekelayo, isiphakamisi kunye nezinye izinto ezilungiswayo.Iyinxalenye esisiseko ye-welding fixture, kwaye ukuchaneka kwayo kukuchaphazela ngokuthe ngqo ukuchaneka kwe-positioning mechanism.I-Circular seam ye-welding automatic machine luhlobo lwezixhobo ze-welding ezizenzekelayo ezinokuthi zizalise zonke iintlobo zeesetyhula kunye ne-annular welds.Ingasetyenziselwa i-carbon steel, i-alloy iron ephantsi, insimbi engenasici, i-aluminium kunye ne-alloy yayo kunye nezinye izinto zomgangatho ophezulu wokuwelda, kwaye ungakhetha i-argon arc welding (icingo okanye i-wire), ukunyibilika kwegesi ye-electrode, ukuwelda kwe-plasma kunye namanye amandla okuwelda. ukwenza i-ring seam ye-welding automatic system.Inokusetyenziswa ngokubanzi kwi-welding ye-hydraulic cylinder, isakhelo sesikhokelo semoto, i-shaft drive, i-cylinder yokugcina igesi, izitya zekhemikhali kunye nezonyango, iitanki zegesi ezinyibilikisiweyo, izixhobo zokulwa nomlilo, ii-roller kunye ne-cylinder yokugcina ulwelo. kwimigca yemigodi kunye nemveliso, njl.

Ukuqukuqela kokuSebenza

1. Ifumene iodolo yokuthenga-——->2. Uyilo-——->3. Ukuqinisekisa umzobo/izisombululo-——->4. Lungisa izixhobo-——->5. CNC-——->6. CMM-——->6. Ukudibanisa-——->7. CMM-> 8. Ukuhlolwa-——->9. (uhlolo lwecandelo le-3 ukuba kukho imfuneko)-——->10. (ngaphakathi/umthengi kwisiza)-——->11. Ukupakisha(ibhokisi yomthi)-——->12. Ukuhanjiswa

Ukunyamezela ukuVeliswa

1. I-Flatness ye-Base Plate 0.05/1000

2. Ukutyeba kweBase Plate ±0.05mm

3. IDatamu yendawo ±0.02mm

4. Umphezulu ±0.1mm

5. Izikhonkwane zokuHlola kunye neMingxunya ± 0.05mm

-300x3001.png)

.png)

.png)