UMvelisi weWelding egqwesileyo yeemoto kunye neFactory eTshayina

Uphuhliso lweNkampani

- Kwi-2011, i-TTM yasekwa eShenzhen.

- Ngo-2012, Ukufudukela e-DongGuan;Ukwakha ubudlelwane bentsebenziswano kunye neMagna International Inc.

- Ngo-2013 Ukwazisa izixhobo eziphucukileyo.

- Kwi-2016, Yazisa izixhobo ezinkulu zeCMM kunye nezixhobo ze-CNC ze-5 axis;Ibambisene ne-OEM Ford eGqibeleleyo iiprojekthi zePorsche, iLamborghini kunye neTesla CF.

- Ngo-2017, Ukufudukela kwindawo yangoku yesityalo;I-CNC yonyuswa ukusuka kwi-8 ukuya kwi-17 isethi.ULungiso lwezoThutho eziPhezulu kunye neJigs Co.Ltd yasekwa

- Ngo-2018, Isebenzisana ne-LEVDEO yeemoto kwaye yagqiba umgca wokuvelisa i-automotional.I-4-axis high-speed CNC yaziswa, i-Qty iyonke ye-CNC yafikelela kwi-21.

- Ngo-2019, i-Dongguan Hong Xing Tool & Die Manufacturer Co., Ltd yasekwa.(Inkonzo yokumisa enye) Isebenzisana noTesla Shanghai kunye neSodecia eJamani.Yakha ilabhoratri entsha ye-R&D yokuzenzela.

- Ngo-2020, Isebenzisana ne-OEM ISUZU e-SA ;Kugqitywe i-RG06 One-Stop Service.

- Ngo-2021, ukuqhubela phambili ngenkolelo esemgangathweni yokwenza ishishini elikumgangatho wehlabathi.

- Kwi-2022, i-ofisi yeQela le-TTM yasekwa kwisiXeko saseDongguan, iNew CNC 4 axis * iiseti ezi-5, iNew Press * iitoni ezingama-630, iHexagon Absolute Arm.

- Ngo-2023, i-TTM yakha iplanti entsha yokujonga i-fixture kunye neshishini le-welding fixture;ukongeza omnye 2000T press.

UkuJonga iFixture & Welding Jigs Factory (Iyonke indawo: 9000m²)

IziXhobo zeSitampu kunye neFactory yaMacandelo aSetyenzisiweyo (Iindawo iyonke: 16000m²)

IiNkcazo zeeMveliso

| Igama lemveliso | Welding Fixture |

| Isicelo | I-CCB yeemoto, i-Front End, i-WS Spring Link, i-Front Bumper njl. |

| Uhlobo lwe-Welding | I-Spot Welding, i-Arc welding, (i-CNC / i-Assembly) i-welding ekhethekileyo |

| I-Pneumatic Component Brand | SMC, FESTO, TUENKERS, CKD, Manual clamp |

| Uphawu lwecandelo loMbane | OMRON, Mitsubishi, Siemens, Baluff |

| Isixhobo (Isithintelo, iPin yokuBopha) | 45 # Intsimbi, ubhedu, intsimbi engatyiwa |

| Indlela yokusebenza | I-Robot Welding, i-Welding Manual, i-Welding ekhethekileyo yomatshini |

| Indlela yokulawula | Ulawulo loMoya (iValve yoLawulo lwe-Pneumatic), uLawulo loMbane(iValve ye-Solenoid ), i-Manual, Akukho valve ye-solenoid efunekayo. |

| Indlela yokubamba | I-pneumatic, iManuwali |

| Indlela yoNxibelelwano kunye ne-Welding Cell | EtherCAT, PROFINET, CC-LINK |

| Ibhokisi yoNxibelelwano loNxibelelwano | Indlela yebhokisi yombane yombane, uhlobo olukhawulezayo lwesokhethi, uhlobo lwesiqithi sevalve yeSolenoid |

| I-Welding Fixture Base Type | Ilungiswe emgangathweni, iPositioner/Flip Tye |

| Indlela yokuBopha | Ityhubhu yomaleko omnye, ityhubhu yokubuyiswa komlilo, iCopper/Stainless Steel Tube |

| Unyango lweFixture Surface | Ukupeyinta, Ukupeyinta+I-Oxidization emnyama, i-Zinc-Coated, i-Powder Painting |

| Ixesha lokukhokhela | Iiveki ezi-2-4 zoyilo kunye nokuphononongwa koyilo; Iiveki ezili-10-12 zokuvelisa emva kokuvunywa koyilo 7-10 Iintsuku zokusebenza zokuthunyelwa ngomoya; Iiveki ezi-4-5 zokuphunga ulwandle |

| Yifa Ubomi | Kuxhomekeke kumthamo wemveliso yomthengi |

| I-Inshurensi esemgangathweni | Ukuhlolwa kweCMM Vavanya ngeeSampulu Onsite Thenga-Off Ividiyo ekwi-Intanethi yeNkomfa yeWebhu yokuthenga Thenga-Off Iingxaki zokuSombulula |

| Iphakheji | Iibhokisi zokhuni zeesampulu;Iibhokisi zoMthi okanye iiPallets zokulungiswa; |

Iimotoizixhobo zokuweldazizixhobo ezibalulekileyo kwinkqubo yokwenziwa kweemoto.Ezi zilungiso zikhethekileyo ziyilelwe ukuqinisekisa ulungelelwaniso oluchanekileyo kunye nokuhlanganiswa kwamacandelo ahlukeneyo, ukuququzelela i-welding ye-chassis, iipaneli zomzimba, kunye namanye amalungu abalulekileyo.Kolu qwalaselo lubanzi, siza kuphonononga imiba ephambili yokulungiswa kweewelding zemoto, kubandakanya ukubaluleka kwazo, ukuqwalaselwa koyilo, ukwenziwa, ulawulo lomgangatho, kunye nendima yabo kushishino lweemoto.1. Ukubaluleka kwe-Automotive Welding Fixtures:

Izixhobo ze-welding ze-Automotive zidlala indima ebalulekileyo ekuveliseni iimoto ngezizathu ezininzi: Ukuchaneka: Ziqinisekisa ukulungelelaniswa okuchanekileyo kwamacandelo, okukhokelela kwi-welds engaguqukiyo kunye nechanekileyo.Oku kubaluleke kakhulu kwisidima solwakhiwo kunye nokhuseleko lwesithuthi.

Ukusebenza kakuhle: Izixhobo ze-welding zikhawuleza inkqubo yendibano, ukunciphisa ixesha lokuvelisa kunye neendleko zabasebenzi.UQinisekiso loMgangatho: Ngokubamba iinxalenye kwindawo ezichanekileyo, izilungiso zinciphisa umngcipheko weempazamo kunye neziphene kwimveliso yokugqibela.Ukungaguquguquki: Ukulungiswa kuzisa iziphumo ezingaguqukiyo, kungakhathaliseki inqanaba lesakhono somsebenzisi, into ebalulekileyo ekufezekiseni umgangatho wesithuthi esifanayo.2. Iingqwalasela zoyilo: Ukuyila izixhobo zokuwelda iimoto yinkqubo entsonkothileyo ebandakanya uqwalaselo ngononophelo lwemiba eyahlukeneyo: Imodeli yesithuthi: Uyilo lwesixhobo kufuneka luhambelane nendlela ethile kunye nemodeli yesithuthi esiveliswayo.Oku kufuna ukuqonda okunzulu kweemfuno zendibano yesithuthi.Ukuma kweNdawo: Uluhlu kufuneka lubeke ngokuchanekileyo amacandelo ahlukeneyo esithuthi, njengeepaneli zomzimba, amacandelo e-chassis, kunye nezixhobo zefreyimu.Oku kubandakanya iindawo ezichanekileyo zendawo, iindlela zokubambelela, kunye nezakhiwo zenkxaso.Ukunyamezela kunye nokulungelelaniswa: Iinjineli kufuneka ziqwalasele ukunyamezela okuqinileyo kunye neemfuno zokulungelelaniswa ukuqinisekisa ukuba amacandelo ahambelana ngokugqibeleleyo.

Ukukhethwa kweMathiriyeli: Ukhetho lwemathiriyeli yokulungisa lubalulekile.Kufuneka yomelele, imelane nobushushu, kwaye yomelele ukuze imelane nenkqubo ye-welding.I-Ergonomics: Ukulungiswa kufuneka kulungiselelwe ukukhululeka kokusetyenziswa kunye nokhuseleko lwabaqhubi.Oku kubandakanya ukuqwalaselwa kokufikelela, ukubonakala, kunye ne-ergonomics ngexesha lokusebenza kwe-welding.3. Ukwenziwa kweFixture:

Ukwenziwa kwezixhobo zokuwelda iimoto kubandakanya izigaba ezininzi:

Uyilo lweCAD: Abaqulunqi benza imodeli ye-3D ye-CAD eneenkcukacha yomdlalo, ichaza indawo, ukuqhelaniswa, kunye neendawo zokubambelela kwicandelo ngalinye.Ukukhethwa kweMathiriyeli: Ngokusekwe kwiinkcukacha zoyilo, izixhobo ezifanelekileyo, ngokuqhelekileyo intsimbi okanye i-aluminium, zikhethwa kulwakhiwo lwezixhobo.Ukwenziwa kwecandelo: Amalungu omntu ngamnye, kubandakanywa izakhiwo zenkxaso, iintambo, kunye nezinto zokubeka, zenziwe ngokuchanekileyo kusetyenziswa umatshini we-CNC kunye nobunye ubuchule obukhethekileyo.I-Welding kunye neNdibano: Ii-welders ezinobuchule kunye neengcali zidibanisa amacandelo, ziqinisekisa ukuba zihambelana ngokuchanekileyo nangokukhuselekileyo.Uvavanyo: Isixhobo sivavanywa ngamandla ukuqinisekisa ukuba siyahambelana nokunyamezelana okufunekayo ukuwelda ngokuchanekileyo.Oku kubandakanya uvavanyo lwamalungu esithuthi.Ulungelelwaniso: Umzobo ulungelelaniswa ukuqinisekisa ukuba uhlala ulungelelwaniso olugqibeleleyo kwaye ugcina imfezeko yesakhiwo.4. Ulawulo loMgangatho: Ukugcina imigangatho ekumgangatho ophezulu kuyo yonke inkqubo yokwenziwa kwezixhobo kubalulekile: Ukuhlolwa: Uhlolo oluthe gqolo lwenziwa ukuqinisekisa ukuchaneka, ukuqina, kunye nokusebenza kwamacandelo okufakela.

Ukujongwa kokunyamezela: Imilinganiselo echanekileyo kunye nokuhlolwa kokunyamezela kuyenziwa ukuze kuqinisekiswe ukuba i-fixture iyahlangabezana nemigangatho efunekayo.

Ukuqinisekiswa kokulungelelaniswa: Ukulungiswa kuqinisekisiwe ukuqinisekisa ukuba bagcina ukulungelelaniswa okuchanekileyo kunye nokuqhelaniswa kwendibano.5. Indima kuShishino lweziThuthi: Izixhobo zokuwelda iimoto ziyinxalenye yenkqubo yokwenziwa kweemoto: I-Chassis Welding: Izixhobo ziqinisekisa ukulungelelaniswa ngokuchanekileyo kwamacandelo e-chassis, kubandakanywa amacandelo efreyimu kunye namacandelo okunqunyanyiswa.I-Body Panel Welding: Babamba iipaneli zomzimba, ezinje ngeengcango, iihoods, kunye neefenders, kwindawo ezichanekileyo zokudibanisa i-welding, igalelo kwintembeko yesakhiwo sonke sesithuthi.I-Welding ye-Seam: Ukulungiswa kusetyenziswa kwi-welding ye-seams, i-joints, kunye nokudibanisa ukudala iibhondi ezinamandla nezithembekileyo.

I-Welding Automation: Kwiimeko ezininzi, ukulungiswa kwe-welding zidibaniswe kunye neeseli ze-robotic welding ukwenzela ukuveliswa okuzenzekelayo, ukuphucula ngakumbi ukusebenza kakuhle kunye nokuhambelana.6. Ukwenziwa ngokwezifiso kwabavelisi beemoto: Abavelisi bezinto zokushisela iimoto badla ngokuba ziingcali ekudaleni izixhobo ezilungiselelwe iimfuno ezikhethekileyo zabenzi beemoto.Ezi zilungiso ziyilelwe ukuhlangabezana nemigangatho kunye neemfuno ezingqamene noshishino, kwaye zinokuhlengahlengiswa kwiimodeli ezahlukeneyo zezithuthi ngaphakathi komgca wemveliso yomenzi.Ukuqukumbela, ukulungiswa kwewelding yeemoto yinxalenye ebalulekileyo yenkqubo yokwenziwa kweemoto.

Izisombululo(Inkonzo yeZisombululo zeTurnkey)

Umzimba kwiiNkqubo zeNdibano eziMhlophe:

I-1, Gqibezela umgca we-Car Body Welding

2, Ukuma yedwaWelding Cell

3,I-Welding Fixtures kunye neJigs:

I-CCB ASSYWelding Fixture, Floor Pan ASSY Welding Fixture, Wheelhouse ASSY Welding Fixture, AB Ring ASSY AB Welding Fixture, Seat ASSY Welding Fixture, Front Seat Cross Member Welding Fixture, Front End ASSY Welding Fixture, Dash Panel ASSY Welding Fixture, Cowl ASSY Welding Fixture kunye neRocker ASSY Umenzi we-Welding Fixture, inkampani yoyilo kunye nefektri.

Inkqubo yoLawulo lwe-ISO ye-Welding Fixture

Iqela lethu leWelding Fixture

Izinto Eziluncedo Zethu

1.Amava atyebileyo kwimveliso ezenzekelayo kunye nolawulo lweshishini.

I-2.Inkonzo ye-One Stop yesixhobo sokupakisha, ukujonga ukulungiswa, izixhobo ze-welding kunye neeseli ukuphumeza ixesha kunye nokugcinwa kweendleko, unxibelelwano olulula, ukunyusa inzuzo yabathengi.

3.Iqela lobunjineli lobuchwephesha lokugqibezela i-GD&T phakathi kwecandelo elinye kunye necandelo lendibano.

I-4.I-Turnkey Solution ye-Service-Stamping Tool, i-Check Fixture, i-Welding Fixtures kunye neeSeli kunye neqela elinye.

I-5.Ikhono elinamandla kunye nenkxaso yobugcisa bamazwe ngamazwe kunye nentsebenziswano yentsebenziswano.

6.Umthamo omkhulu: Ukujonga i-Fixture, iiseti ze-1500 / ngonyaka;I-Welding Fixture kunye neeSeli, iiseti ze-400-600 / ngonyaka;Izixhobo zeStamping, iiseti ze-200-300 / ngonyaka.

Sinabasebenzi abangaphezu kwama-352, i-80% yabo ziinjineli eziphezulu zobugcisa.Icandelo lezixhobo: abasebenzi abayi-130, icandelo le-Welding fixture: abasebenzi abangama-60, Ukujonga icandelo lokulungiswa: abasebenzi abayi-162, Sineqela lokuthengisa kunye neqela lolawulo lweprojekthi, inkonzo yexesha elide yeeprojekthi zaphesheya, ukusuka kwiRFQ ukuya kwimveliso, ukuthunyelwa, emva kokuthengisa, iqela lethu inokusingatha zonke iingxaki kubathengi bethu ngesiTshayina, isiNgesi kunye noLwimi lwesiJamani.

Amava eeProjekthi eziMakhulu kwiiSeli ze-Welding kunye ne-Welding Fixtures

| Iprojekthi yoLungiso oluKhulu lweWelding (2019-2021) | |||||

| Into | Inkcazo | Uhlobo | Igama leProjekthi | Ubuninzi (Iiseti) | Unyaka |

| 1 | I-CCB WF | Arc Welding | VW MEB31 | 60 | 2019-2021 |

| 2 | I-CCB WF | Arc Welding | VW MEB41 | 10 | 2020 |

| 3 | I-CCB WF | Arc Welding | VW 316 | 4 | 2020 |

| 4 | I-CCB WF | Arc Welding | Ford T6 | 8 | 2021 |

| 5 | I-CCB WF | Arc Welding | ISUZU RG06 | 3 | 2020 |

| 6 | I-CCB WF | Arc Welding | Imoto, iBSUV | 6 | 2020 |

| 7 | I-CCB WF | Arc Welding | Bcar,BCAR | 7 | 2020 |

| 8 | I-Pan yoMgangatho WF | Sopt Welding | SK326/0RU_K Karoq RU | 15 | 2019 |

| VW316/5RU_K Tarek RU (19003) | |||||

| 9 | WS Spring Link WF | Arc Welding | WL/WS | 4 | 2019 |

| 10 | Izibiyeli zeCrossmember WF | Arc Welding | WL/WS | 12 | 2019-2021 |

| 11 | Ibhampa yangaphambili iWF | Arc Welding | VW281 | 14 | 2019 |

| 12 | I-Chassis WF | Arc Welding | ISUSU RG06 | 18 | 2019 |

| 13 | I-SL ASY kunye ne-MBR kunye ne-EXT ASY | I-Spot kunye ne-Arc Welding | Ford P703 | 25 | 2019-2021 |

| 14 | I-CCB WF kunye neSeli eSebenzayo | Arc Welding | ISUSU RG06 | 6 | 2020 |

| 15 | Isitulo esiPhambili seLungu le-WF | Sopt Welding | Volkswagen AG MEB316(20001) | 4 | 2020 |

| 16 | Umgangatho wePan WF kunye neeGrippers | Sopt Welding | I-AUDI/ PORSCHE PPE 41(19017 iSigaba soku-1) | 18 | 2020 |

| 17 | Indlu yesondo iWF kunye neGrippers | Arc Welding | Ford BX755(19018) | 6 | 2020 |

| 18 | AB Ring WF kunye Grippers | Arc Welding | Ford BX755(19018) | 14 | 2020 |

| 19 | Dash Panel WF kunye Grippers | Sopt Welding | South Africa Ford T6(17028-1) | 10 | 2020 |

| 20 | Cowl WF kunye Grippers | Spot Welding | South Africa Ford T6(17028-3) | 6 | 2020 |

| 21 | Isiphelo sangaphambili seWF kunye neGrippers | I-Spot kunye ne-Arc Welding | South Africa Ford T6(17025) | 10 | 2020 |

| 22 | I-Rocker WF kunye ne-Grippers | Spot Welding | South Africa Ford T6(19029) | 8 | 2020 |

| 23 | Umgangatho wePan WF kunye neeGrippers | Sopt Welding | I-AUDI/ PORSCHE PPE 41(19017 Isigaba 2) | 63 | 2021 |

| 24 | Ibhampa yangasemva kunye neChassis WF | Arc Welding | Ford P703&J73 | 36 | 2020-2021 |

| Iprojekthi yokuLungisa okuMakhulu (2022) | |||||

| Into | Inkcazo | Uhlobo | Igama leProjekthi | Ubuninzi (Iiseti) | Unyaka |

| 25 | I-Middle Channel yokuQinisa iWF | Sopt Welding | Vinfast VF36 | 8 | 2022 |

| 26 | Umgangatho wePan WF kunye neeGrippers | Sopt Welding | AUDI/ PORSCHE PPE 41(19017 Isigaba 3&4) | 39 | 2022 |

| 27 | I-Pan yoMgangatho WF | I-Sopt Welding kunye ne-Projection Welding | Ford P703 PHEV | 29 | 2022 |

| 28 | Umgangatho wePan WF kunye neeGrippers | Sopt Welding | IPorsche E4 yoMgangatho wePani(21050) | 16 | 2022 |

| 29 | Itonela yoMgangatho WF | Ukumakishwa kweLaser | Itonela yoMgangatho weVW(21008) | 2 | 2022 |

| 30 | Seat ASSY WF kunye Tooling | Arc Welding | BYD Seat ASSY | 40 | 2022 |

| 31 | I-Pan yoMgangatho WF | I-Spot kunye ne-Arc Welding | Ford Refurbishment | 24 | 2022 |

| 32 | I-CCB WF | Arc Welding | I-VW Cyclone CCB(21037) | 10 | 2022 |

| 33 | I-CCB WF | Arc Welding | I-VW MQB37(22022) | 16 | 2022 |

| 34 | I-A&B-Pillar WF | Spot Welding | I-Gestamp GS2203 | 8 | 2022 |

| 35 | Isiseko seSeli yeRobhothi | NA | I-VW Cyclone | 4 | 2022 |

IZiko lokuVelisa iWelding Fixture

Sinokwakha zonke iintlobo zobukhulu obahlukeneyo bokuwelda kubandakanywa ubungakanani obukhulu njengoko sinoomatshini abakhulu be-CNC.Ngezixhobo ezahlukeneyo zoomatshini ezifana nokugaya, ukugaya, oomatshini bokusika iingcingo kunye noomatshini bokugaya, sinokulawula ngokufanelekileyo nangokuchanekileyo inkqubo yokucubungula.

Iiseti ze-25 ze-CNC kunye ne-2 shift esebenzayo

Iseti e-1 ye-3-Axis CNC 3000*2000*1500

Iseti ye-1 ye-3-Axis CNC 3000 * 2300 * 900

Iseti ye-1 ye-3-Axis CNC 4000 * 2400 * 900

Iseti e-1 ye-3-Axis CNC 4000*2400*1000

Iseti e-1 ye-3-Axis CNC 6000*3000*1200

4 Iseti ye-3-Axis CNC 800 * 500 * 530

9 Iseti ye-3-Axis CNC 900 * 600 * 600

5 Iseti ye-3-Axis CNC 1100 * 800 * 500

Iseti ye-1 ye-3-Axis CNC 1300 * 700 * 650

Iseti ye-1 ye-3-Axis CNC 2500 * 1100 * 800

5 Axis CNC -Machine

4 Axis CNC -Machine

Iziko leNdibano ye-Welding Fixture

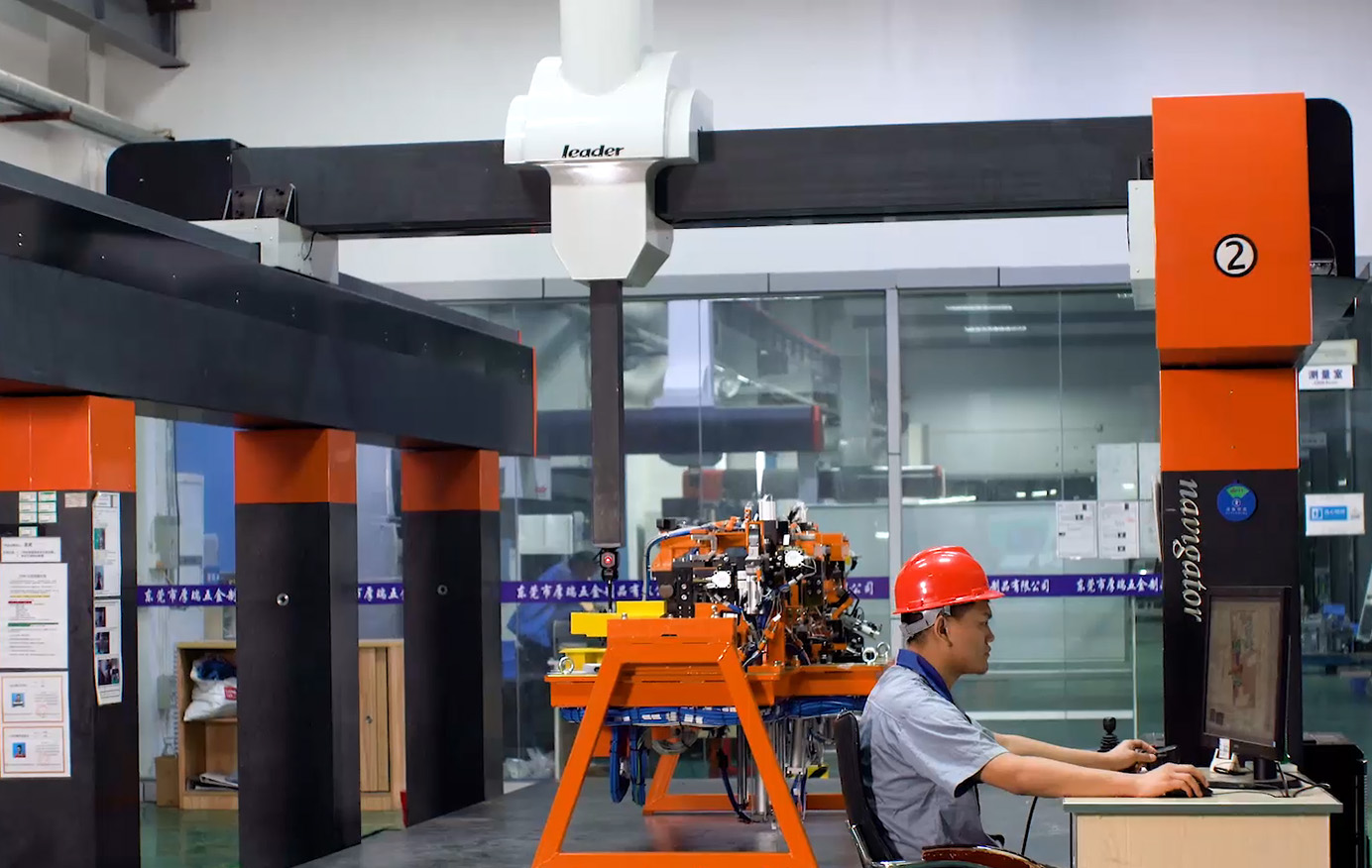

Iziko lokulinganisa le-CMM lokuLungisa i-Welding

Oabasebenzi bakho abaqeqeshiweyo baya kukhathalela lonke ixesha kuyo yonke inkqubo esinayo.Sinokwenza yonke imfuneko kumthengi, ukuba sibe nolwaneliseko olukhulu kwiCMM ngokunjalo.

Iiseti ezi-3 zeCMM, iiShifts ezi-2/usuku(ii-10hrs ngeshifti ngoMvulo-ngoMgqibelo)

CMM, 3000*1500*1000 , Leader CMM, 1200*600*600 , Leader Blue-light Scanner

CMM, 500*500*400, Hexagon 2D Projector, Hardness Tester

.png)

.png)