Iqela le-TTM yinkampani ekwaziyo ukwenza izixhobo zokuwelda iimoto ezizisebenzelayo.Iimveliso zethu zisetyenziswa kakhulu kwindawo yokwenziwa kweemoto, kwaye zithenjwa ngokunzulu kwaye zidunyiswa ngabathengi.Iimveliso zethu ze-automation welding welding ikakhulu zibandakanya iinkqubo zokuwelda iirobhothi, izixhobo zokuwelda i-laser, izixhobo ze-welding ezikhuselweyo zegesi, njl. Ezi mveliso zonke ziyilwe kwaye ziveliswa liqela lethu lobuchwephesha, elibonisa ukusebenza kakuhle okuphezulu, uzinzo kunye nokhuseleko.

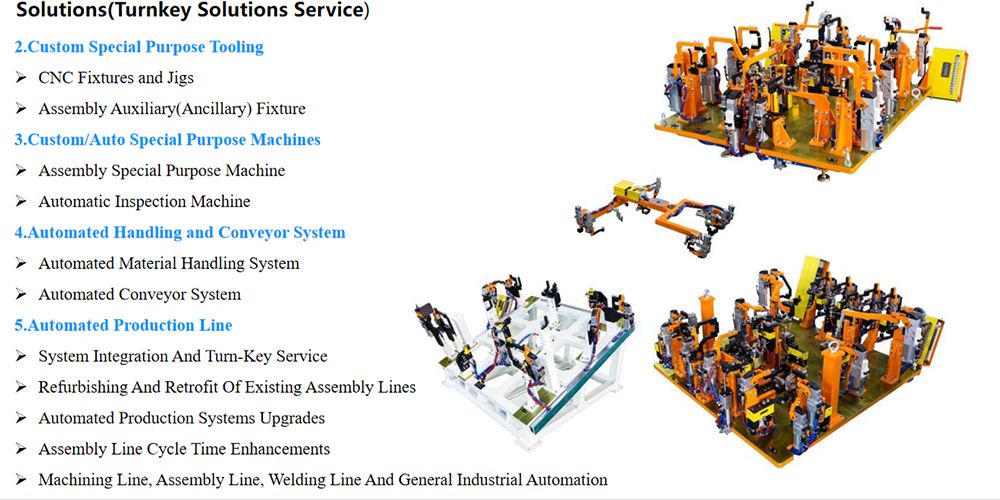

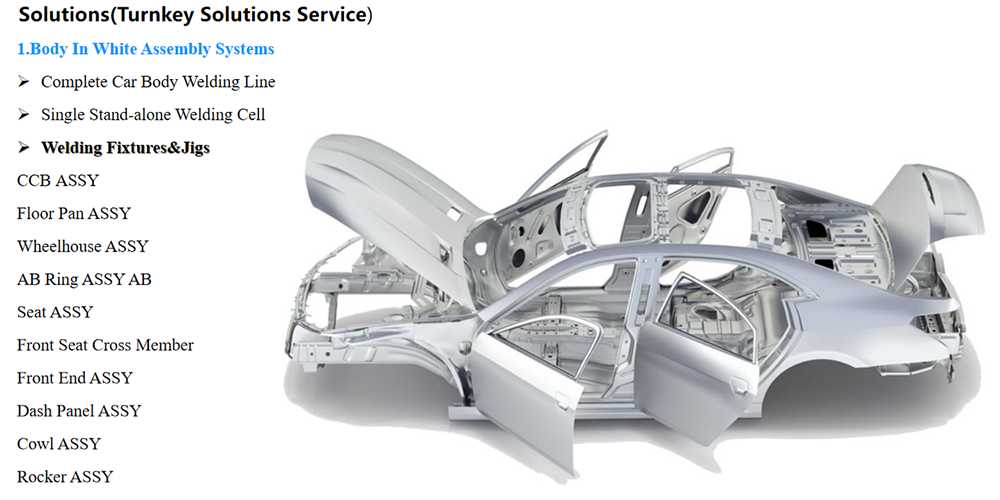

Kuba ubume bemoto buntsonkothile ngakumbi kuneemveliso eziqhelekileyo zoomatshini, inkqubo yokudibanisa kunye ne-welding inzima, kwaye umthamo wemveliso mkhulu, ngakumbi ukuveliswa komzimba wemoto bekusoloko kulishishini elinezicelo eziphezulu zobuchwepheshe.Isitshixo sisikakhulu iirobhothi zokuwelda ezinkulu kunye neekhaltyhuleyitha.Umgca wemveliso we-welding yomzimba owenziwe ngezixhobo zokulayisha amalahle ezizenzekelayo.

Uninzi lomzimba wemoto luqulunqwe ngamacandelo esinyithi kunye neendawo zokugubungela, kunye neendawo ezahlukeneyo ezakhiwe ngaphambili, njengeentsika zomoya, iintsika zocango, iileyili zocango ezingaphezulu, iifestile zangaphambili nangasemva, iipaneli zangaphambili nangasemva, izigqubuthelo eziphezulu, njl. zihlanganiswe nge-welding kunye ne-riveting, phakathi kwayo i-welding linyathelo eliyimfuneko kumgca wokuhlanganisa imoto.

Kwiminyaka yakutshanje, abavelisi beemoto zasekhaya ezinkulu baye bamkela imigca yokuwelda umzimba werobhothi, kwaye uninzi lwabo lubonise amandla obugcisa akhokelayo kwihlabathi.Phakathi kwezi robhothi, iirobhothi ze-welding zenza umlinganiselo omkhulu.

Kwiminyaka yakutshanje, itekhnoloji ye-laser welding body ithe ngokuthe ngcembe ithathe indawo yetekhnoloji ye-welding ye-welding, enokuthi ihlangabezane neemfuno ezigqibeleleyo kulungiso lwamalungu emoto.Ukusebenzisa le teknoloji entsha, ububanzi bomphezulu odibeneyo phakathi kokudibanisa i-workpiece ingancitshiswa, enganciphisi nje imfuno yeepleyiti Kwakhona kwandisa ukuqina komzimba.I-laser welding parts, akukho deformation kwi-welding parts of the parts, isantya se-welding siyakhawuleza, kwaye akukho mfuneko yonyango lobushushu be-post-weld.I-laser welding inesakhono esihle malunga nokusebenza kakuhle, uqoqosho, ukhuseleko, amandla, kunye nokumelana nomhlwa.Kwaye obu buchwepheshe butsha bubuye baba ngoomatshini abaqhelekileyo kunye nezixhobo kwishishini lemveliso.

Iimveliso zethu zokushisela iimoto ezizisebenzelayo zisetyenziswe ngokubanzi kumashishini amaninzi okuvelisa iimoto ukunceda abathengi baqonde imveliso ezenzekelayo, ukuphucula ukusebenza kakuhle kwemveliso kunye nomgangatho, kunye nokudala ixabiso elikhulu kubathengi.Siza kuqhubeka nokukhuthaza ukusungulwa kweteknoloji kunye nophando lwemveliso kunye nophuhliso, ukubonelela abathengi ngeemveliso kunye neenkonzo ezingcono, kwaye sincede uphuhliso loshishino lweemoto.

Ixesha lokuposa: Apr-28-2023

.png)

.png)