Enye yeStop Service Metal Tooling Supplier Stamping Mold Stamping Part

Isitampu seVidiyo yokuMngunda

Metal Stamping Die Specification

| Igama lebrand | OEM |

| Igama lemveliso | Isitampu sentsimbi Die/Mold |

| Ukunyamezelana | +0.002mm |

| Izinto eziphathekayo | SKD11, SKD 61, Cr1 2MOV, D2, SKH9, RM56, ASP23 njl. |

| Uyilo lweSoftware | I-AutoCAD, imisebenzi eqinile, i-PRO / E, i-UG |

| Umgangatho | IS09001-2015 |

| Uhlobo lokungunda | Transfer Die, Single Stamping Die, Progressive die okanye ngokweemfuno zoMthengi |

| Isilingo sokuqala | Kwiintsuku eziyi-15-25 emva kokuba umzobo uqinisekisiwe |

| Ubomi boMngundo | 5-10 iminyaka ukuba sigcine isixhobo kakuhle |

| Ukuqinisekisa umgangatho | Ungathumela uyilo lomtya wokufa, ividiyo yokuvavanya, isatifikethi sokuhlola kunye nesampulu yemveliso |

| Iphakheji | Iingxowa ze-PE kunye neebhokisi zeemveliso, ityala leplanga lokufa / ukungunda, okanye njengeemfuno zomthengi |

Okungakumbi malunga neStamping Die

Imveliso yanamhlanje yokucofa isitampu yindlela yokuvelisa eqhubekayo.Ngenxa yokubandakanyeka kunye nokungenelela kobuchwepheshe obuphezulu, imowudi yokuvelisa isitampu iye yavela ngokuthe ngcembe ukusuka ekusebenzeni kwencwadana yokuqala ukuya kwimveliso edibeneyo.

Inkqubo yemveliso ithe ngokuthe ngcembe yaqonda umatshini, i-automation, kunye nesalathiso sophuhliso olukrelekrele, oludibeneyo.Ukufezekiswa kwe-automation ye-stamping operation kubonakalisa iingenelo zokhuseleko, ukusebenza kakuhle kunye nokugcinwa kwezinto eziphathekayo, eziye zaba yindlela yokuphuhlisa i-stamping die production.

Kubomi bethu bemihla ngemihla, izitya ezininzi zigximfizwa, njengeesitya zerayisi ezingenasici.Iqulathe ipleyiti yentsimbi engqukuva ecinezelwe ngumngundo kumatshini wokushicilela.Ngaloo ndlela, ukunyathela okubandayo luhlobo lwendlela yokulungisa uxinzelelo lwesinyithi eyenza uxinzelelo kwiipleyiti ezahlukeneyo zetsimbi (okanye ezingezizo ezentsimbi) ukuze zahlule okanye zikhubazeke kubushushu begumbi (imeko ebandayo).

Akunjalo kuphela kwitekhnoloji entsha emininzi, itekhnoloji entsha ekuvelisweni koluhlu olubanzi lwezicelo, njengokujikeleza, ukubumba okuthambileyo, ukwenziwa kwesantya esiphezulu samandla, kodwa kwakhona kukumtsiba okusemgangathweni ekuqondeni nasekubambeni inkqubo yesitampu.

Amandla oNikezo lweTTM

Ukubonelela ngobuchule:500 iSeti/iSeti ngonyaka

Ukupakishwa kunye nokuhanjiswa

Iinkcukacha zokuPakisha:

Ukupakishwa kweCase yeplanga

Khangela izibuko:

Shenzhen

Umzekelo woMfanekiso:

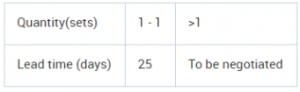

Ixesha lokukhokhela:

.png)

.png)