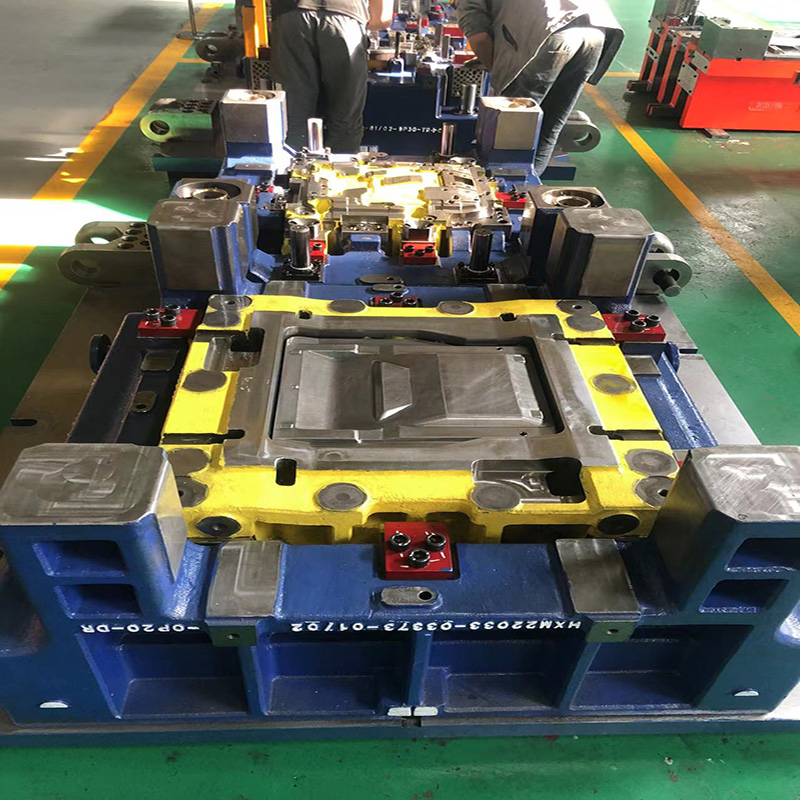

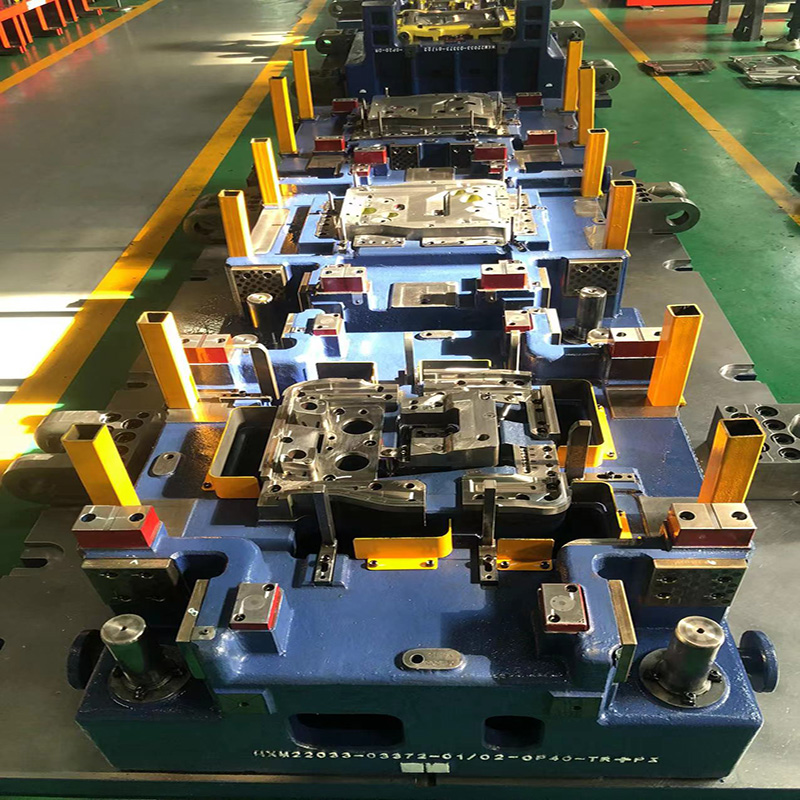

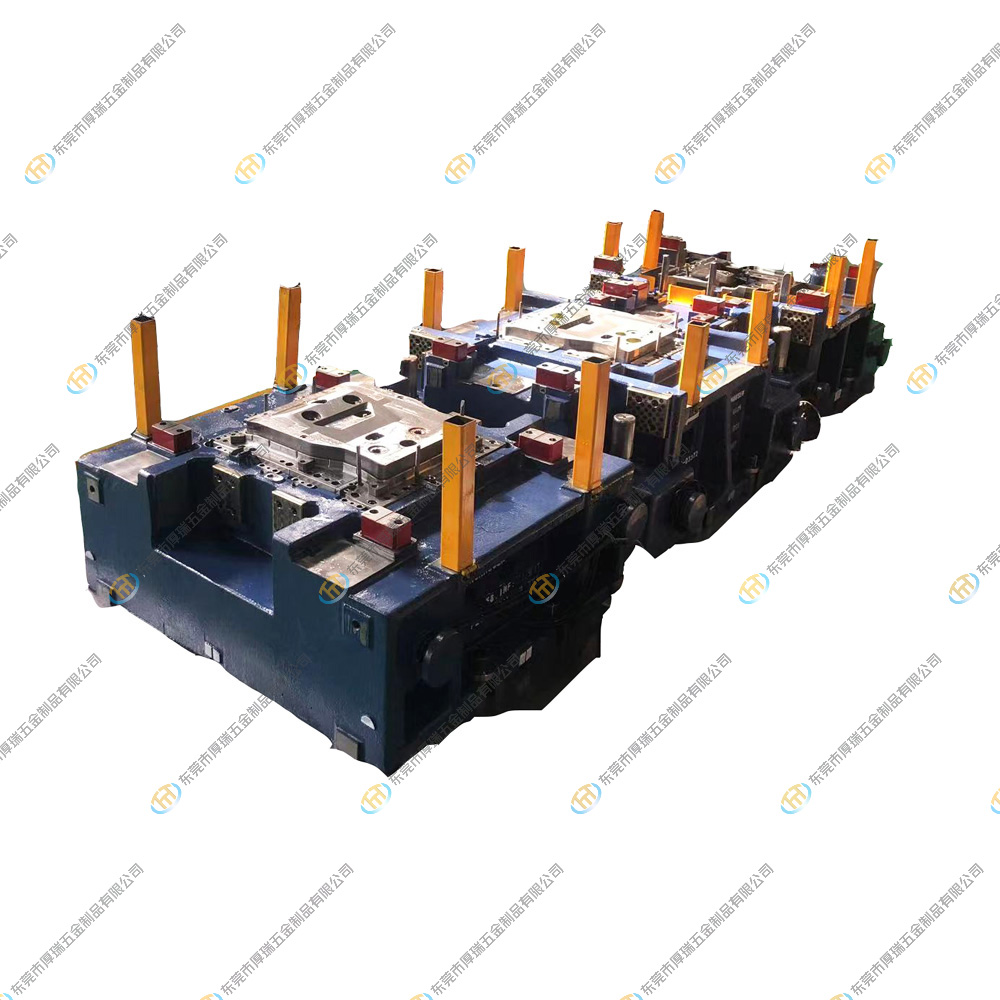

Isitampu esichanekileyo siFa ngenxa yeSitulo seMoto Inxalenye yeSitampu seMetal Die abavelisi beMold

Ividiyo

Iinkcukacha zeMveliso

Intshayelelo eneenkcukacha

Inkqubo yesitulo semoto Iimveliso ze-hardware zineemfuno eziphezulu zecandelo elikhanyayo ibhanti, ukuchaneka kwendawo yomngxuma, ukuphakama komngxuma kunye nokubonakala komphezulu we-peripheral.Phakathi kwabo, itekhnoloji yesitampu yeyona teknoloji iphambili kuyilo lwezixhobo zemoto.Uyilo lwe-TTM yesihlalo semoto inxalenye ye-mold stamping die inokunciphisa ngokufanelekileyo iindleko zeemveliso kunye nokuphucula umgangatho weemveliso, ukunciphisa ixesha lokwakha, njl.

Ukuqukuqela kokuSebenza

1. Ifumene iodolo yokuthenga-——->2. Uyilo-——->3. Ukuqinisekisa umzobo/izisombululo-——->4. Lungisa izixhobo-——->5. CNC-——->6. CMM-——->6. Ukudibanisa-——->7. CMM-> 8. Ukuhlolwa-——->9. (uhlolo lwecandelo le-3 ukuba kukho imfuneko)-——->10. (ngaphakathi/umthengi kwisiza)-——->11. Ukupakisha(ibhokisi yomthi)-——->12. Ukuhanjiswa

Ukunyamezela ukuVeliswa

1. I-Flatness ye-Base Plate 0.05/1000

2. Ukutyeba kweBase Plate ±0.05mm

3. IDatamu yendawo ±0.02mm

4. Umphezulu ±0.1mm

5. Izikhonkwane zokuHlola kunye neMingxunya ± 0.05mm

.png)

.png)