TTM Machinery Precision Die kunye Stamping Part Sample

Ividiyo

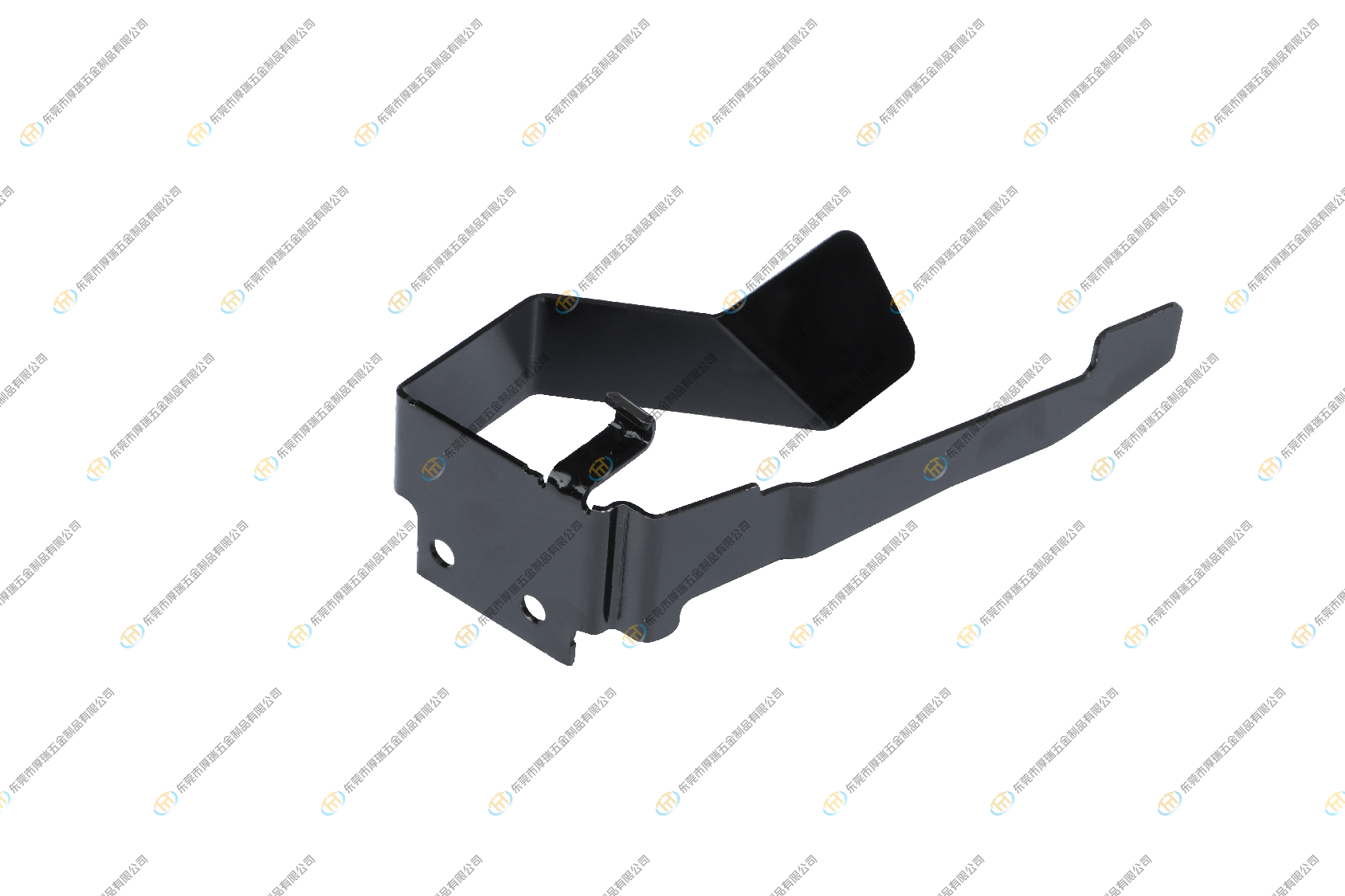

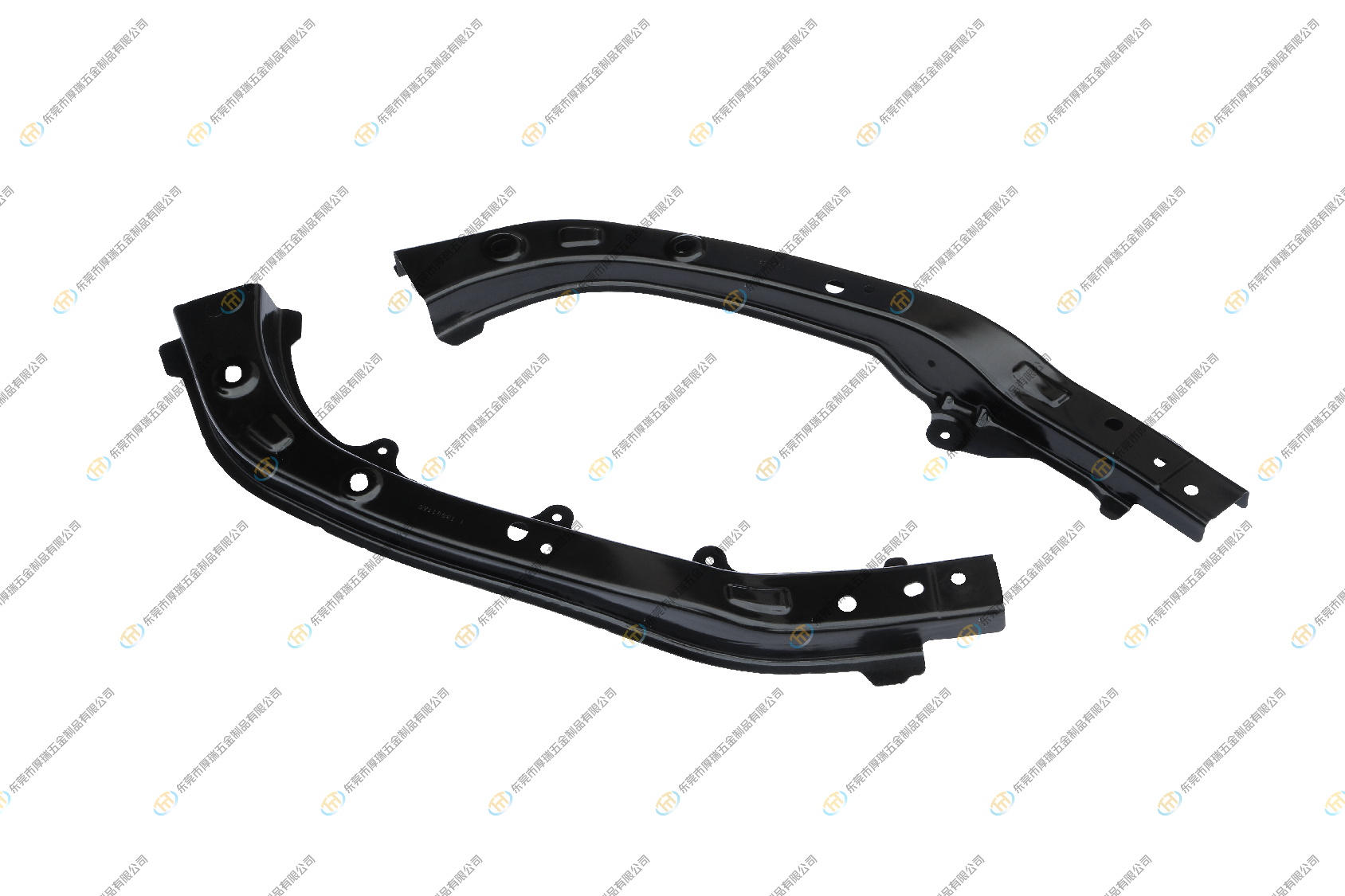

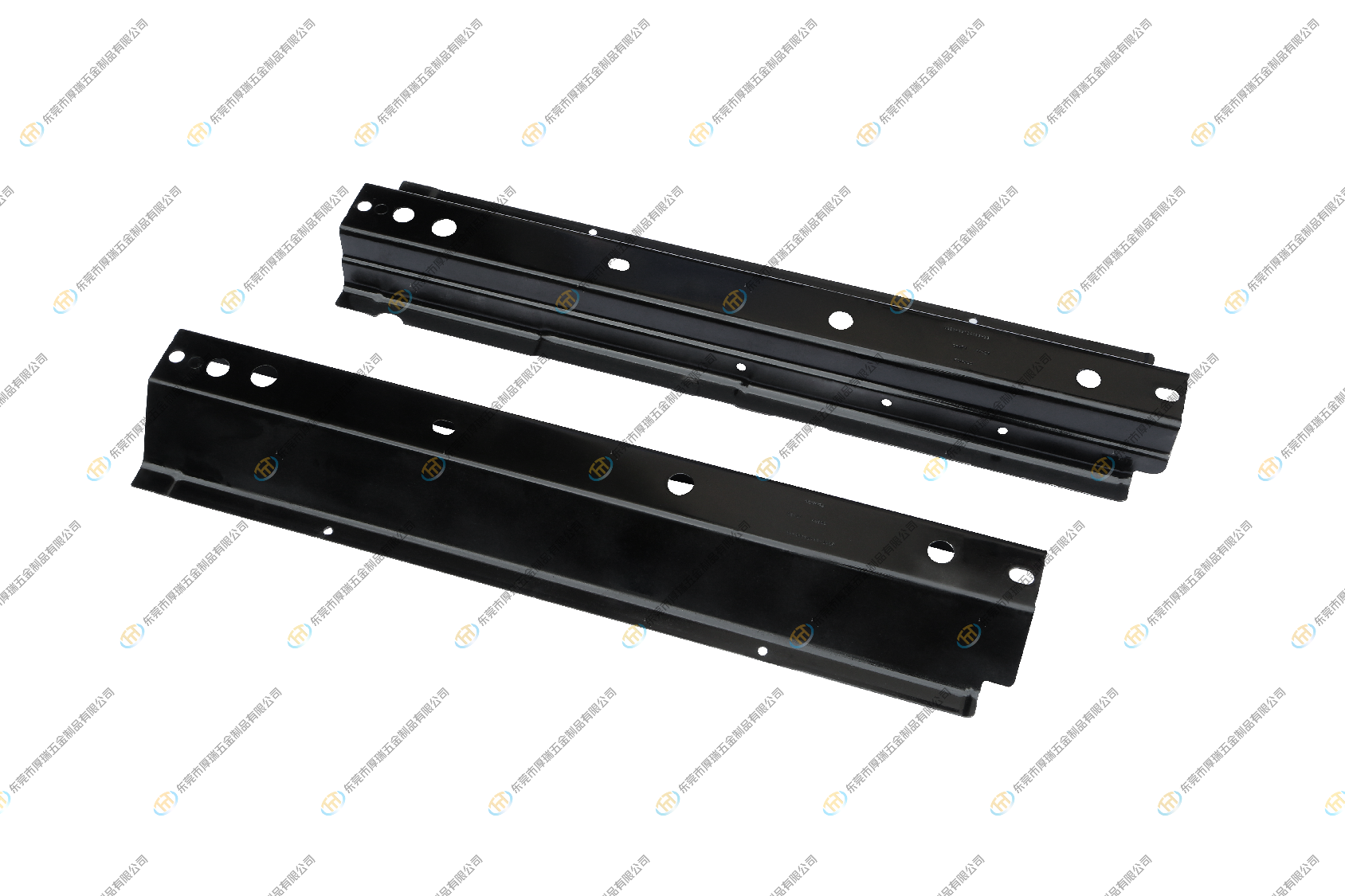

Amacandelo

- Isitulo ngasemva

- IBattery Cradle

- I-Cradle

- Ijelo eliphambili

- njl.

Imifanekiso yeMveliso

Intshayelelo

Amalungu esitampu abhekisa kumalungu enziwe ngokugximfiza amacwecwe esinyithi ngokufa.Ineenzuzo zokuchaneka okuphezulu, ubunzima obulula, amandla aphezulu, kunye neendleko eziphantsi, kwaye isetyenziswa kakhulu kwiimoto, i-elektroniki, oomatshini kunye namanye amacandelo.Iisampulu zenxalenye yesitampu zezinye iisampulu eziveliswe ngenjongo yokuqinisekisa ukuba uyilo luyahlangabezana neemfuno, ukujonga umgangatho, nokukhuthaza imarike.Ngokwesiqhelo, iisampulu zamalungu estampu eziveliswe yi-TTM kufuneka zihlolwe ngokungqongqo kwaye zivavanywe ukuqinisekisa ukuba ukusebenza kwazo kunye nomgangatho ziyahlangabezana nemigangatho kwaye ziyahlangabezana neemfuno zabathengi.

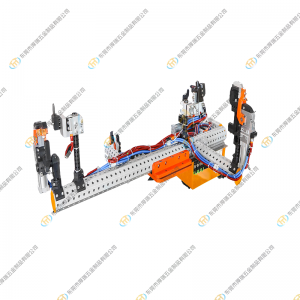

Ukuqukuqela kwethu kokuSebenza

1. Ifumene iodolo yokuthenga-——->2. Uyilo-——->3. Ukuqinisekisa umzobo/izisombululo-——->4. Lungisa izixhobo-——->5. CNC-——->6. CMM-——->6. Ukudibanisa-——->7. CMM-> 8. Ukuhlolwa-——->9. (uhlolo lwecandelo le-3 ukuba kukho imfuneko)-——->10. (ngaphakathi/umthengi kwisiza)-——->11. Ukupakisha(ibhokisi yomthi)-——->12. Ukuhanjiswa

Ukunyamezela ukuVeliswa

1. I-Flatness ye-Base Plate 0.05/1000

2. Ukutyeba kweBase Plate ±0.05mm

3. IDatamu yendawo ±0.02mm

4. Umphezulu ±0.1mm

5. Izikhonkwane zokuHlola kunye neMingxunya ± 0.05mm

.png)

.png)