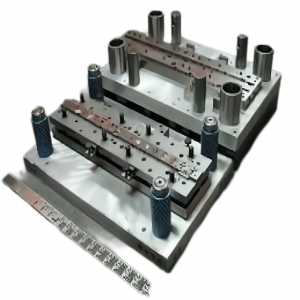

Welding Fixture For Cross Member WS Spring Link

Ividiyo

Iinkalo zeSicelo

Ulawulo lomgangatho woshishino lweemoto

Amandla okuvelisa umgca wemoto ayaphucuka

Inkcazo

| Uhlobo lokuLungisa: | Arc Welding |

| Ubungakanani: | 1800x1300x900mm |

| Ubunzima: | 125KG |

| Izinto: | Ulwakhiwo oluphambili: isinyithi Inkxaso: isinyithi |

| Unyango lomphezulu: | Isiseko seplate: Electroplating Chromium kunye Black Anodized |

Iinkcukacha zeMveliso

Intshayelelo eneenkcukacha

Le yibhetshi ye-welding fixture ye-WL Cross Ilungu le-WS Spring Link, ngokupheleleyo kwiiseti ze-2, senzele umthengi wethu waseCanada.I-spring chuck shank yi-cylindrical fixture efakwe kumatshini wokugaya ukuvalela i-drill okanye i-milling cutter.Faka i-chuck kwinut yokutshixa kwaye ngobunono ujije i-nut yesitshixo nge-spring chuck kwi-shank, isinxibelelanisi okanye intambo yokusonta.Kuxhomekeke kukuqina kwentsimbi eelastiki ukuqinisa, i-clamp ekhululekileyo ilula, isetyenziswa kakhulu ekukhanyeni ukukhanya, izixhobo zokusika umthwalo ophakathi.Ihlala isetyenziselwa ukugoba izixhobo zokusika ezinje ngee-mill, ii-drill bits, iimpompo, ii-reamers kunye ne-drill ephakathi.Guqula uluhlu lwe-clamping ngokutshintsha ukuqokelela okuhlukeneyo.Xa udibanisa, inxalenye yentambo ye-spring chuck, i-lock nut kunye nendawo yokubeka indawo kunye ne-cone surface kufuneka icocwe.Ngexesha lofakelo lwe-chuck kunye ne-lock nut, i-chuck kunye ne-lock nut kufuneka ithotywe kwi-Engile ethile kwaye ifakwe kwi-lock slot ye-lock nut.Musa ukusebenzisa i-torque ye-wrench eyongeziweyo enamandla kakhulu, ukuthintela isixhobo esibi se-meteorite kunye nokulungiswa.

Ukuqukuqela kokuSebenza

1. Ifumene iodolo yokuthenga-——->2. Uyilo-——->3. Ukuqinisekisa umzobo/izisombululo-——->4. Lungisa izixhobo-——->5. CNC-——->6. CMM-——->6. Ukudibanisa-——->7. CMM-> 8. Ukuhlolwa-——->9. (uhlolo lwecandelo le-3 ukuba kukho imfuneko)-——->10. (ngaphakathi/umthengi kwisiza)-——->11. Ukupakisha(ibhokisi yomthi)-——->12. Ukuhanjiswa

Ukunyamezela ukuVeliswa

1. I-Flatness ye-Base Plate 0.05/1000

2. Ukutyeba kweBase Plate ±0.05mm

3. IDatamu yendawo ±0.02mm

4. Umphezulu ±0.1mm

5. Izikhonkwane zokuHlola kunye neMingxunya ± 0.05mm

Inkqubo

I-CNC Machining (Ukugaya / Ukuguqula), Ukugaya

Electroplating Chromium kunye Black Anodized Treatment

Iiyure zokuyila (h): 40h

Yakha iiyure (h): 150h

Ulawulo lwemeko

I-CMM (i-3D Coordinate Measuring Machine), Vms-2515G 2D Projector, HR-150 A Hardness Tester

Isiqinisekiso seQela leSithathu senziwe nguShenzhen Silver Basis Testing Technology Co., Ltd, ISO17025 Certified

.png)

.png)