Amalungu omzimba wemoto ye-bumper yangaphambili Ukujonga ukulungiswa

Ividiyo

Umsebenzi

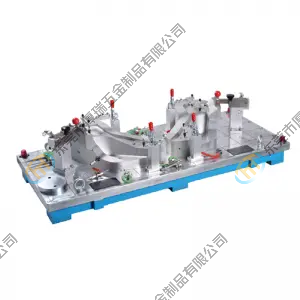

Kulawulo lomgangatho wokuhlolwa kweBumper yangaphambili kunye nenkxaso yokuphucula izinga lomthamo wemveliso yemoto

Inkcazo

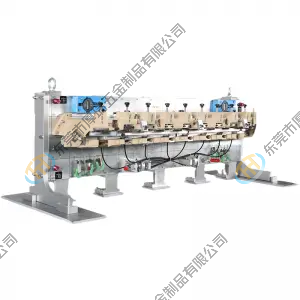

| Uhlobo lokuLungisa: | Ukujonga uLungiso lweBumper engaphambili |

| Ubungakanani: | 1480*360*600 |

| Ubunzima: | 127KG |

| Izinto: | Ulwakhiwo oluphambili: isinyithi Inkxaso: isinyithi |

| Unyango lomphezulu: | Isiseko seplate: Electroplating Chromium kunye Black Anodized |

Iinkcukacha zeMveliso

Intshayelelo eneenkcukacha

Isixhobo sokuhlola sidlala indima yokuxhasa isixhobo sokuhlola sonke kwaye sisisiseko sesixhobo sokuhlola.Iqinile, izinzile yimfuneko yayo esisiseko.Ikwadlala indima yokuthwala i-mobile inspection fixture.Izixhobo zokuhlola ezinkulu ngokubanzi ziphonswe njenge-skeleton yonke kunye nesiseko, efuna ukuba i-roller ehambayo ifakwe kwikona nganye kwiikona ezine, ngoko ke "isiseko" esipheleleyo siquka ipleyiti esezantsi, i-skeleton kunye ne-roller, phakathi kwayo i-plate ephantsi. yimfuneko.Izixhobo zokuhlola ezincinci zikwaluncedo umbhobho wentsimbi odityaniswe kwisakhelo sokuhomba, ulula kwaye uluncedo.IIMFUNO EZOngezelelweyo - I-Spring washers yamandla aneleyo kufuneka ibonelelwe kuzo zonke iintlobo zokudityaniswa kwe-bolted kwi-plate yesiseko.

Isakhelo sokulungiswa sinokuba luhlobo lwekholamu yokwahlula ukuba isetyenziselwa kuphela ukuhlolwa kweengxenye zendibano.Uqhagamshelo kunye nepleyiti esezantsi ithatha i-screw skeleton kwaye isiseko senziwe ngokubanzi ngealloyi ye-aluminium kunye nokuchaneka okuphezulu komatshini.Shanghai Volkswagen idla ngokucebisa zasekhaya: GBZL101.Izinto eziphathekayo kufuneka zihambe ngenkqubo yonyango lokushisa njengokususwa koxinzelelo: i-gauge encinci ithatha i-aluminium alloy base plate.

Isenokwahlulwa ibe ngamacandelo okubona (njengomphezulu osebenzayo) kunye neendawo ezingabonwayo (ezifana nomphezulu ongasebenziyo).Izithuthi zangaphakathi kunye neendawo zangaphandle ze-trim, ngokukodwa iinxalenye zeplastiki, zinendawo enzima yendawo kunye neempawu zasekuhlaleni, ukuqina okungahambi kakuhle kunye nezinye iimpawu, okubangela ukubeka indawo, ukuxhasa kunye nokubethelwa kunzima, ngoko ke uyilo lobume benxalenye yesixhobo lubaluleke kakhulu.Emva kokuba uyilo lwecandelo lomzimba wesixhobo lugqityiwe, indawo kunye nobukhulu bendibano ephantsi inqunywe ngokuhambelana nomzimba wesixhobo, kwaye ikhadi lemilo libekwe kwicandelo eliphambili eliza kuvavanywa.

Kwizinto eziphathekayo zohlobo lomzimba, umhloli omkhulu kufuneka athathe izinto ze-resin (iplastiki yobunjineli) enokuthi iqhutywe, kwaye umhloli omncinci unokusebenzisa i-aluminium alloy.

Amanqaku aphambili oyilo lwesakhiwo.

Ngaphambi kokuyila isixhobo sokuhlola, qiniseka ukuba ufunda ngononophelo imizobo yemveliso, "uqonde kakuhle" ubungakanani kunye neemfuno ezihambelanayo zamacandelo, ukuba kunokwenzeka, uhlolisise ngononophelo iisampuli kunye neemoto zesampula, kunye nesakhiwo sangaphakathi samalungu ahloliweyo kunye nangaphandle. Ubudlelwane bokulungelelanisa - okokuqala, ukufikelela ukuqonda okucacileyo kwentliziyo.Isakhiwo sesixhobo sokulinganisa samanje kufuneka siqwalaselwe ngokupheleleyo ekuyilweni kokusetyenziswa kwayo njengenkxaso yokulinganisa (inkxaso yokulinganisa luhlobo lwenkxaso encedisayo xa ulinganisa iinxalenye kunye nomatshini wokulinganisa ulungelelaniso), ukudibanisa isixhobo sokulinganisa kunye nenkxaso yokulinganisa ibe yinye, enokusebenza ngempumelelo. gcina iindleko zokuvelisa.

Ngokomgaqo, indawo yecandelo elifunyenweyo elibekwe kwisixhobo kufuneka lihambelane nendawo yalo kwinkqubo yokulungelelanisa umzimba, kwaye ireferensi yomlinganiselo kufuneka ibekwe kwinkqubo yokulungelelanisa umzimba.Qinisekisa ukuba indiza yereferensi kunye nomngxuma wereferensi kwisiseko ingasetyenziswa ngokulula ukuseka inkqubo yolungelelwaniso lwereferensi ehambelana nenkqubo yokulungelelanisa umzimba, oko kukuthi, ulungelelwaniso oluphawulwe ngenqwelomoya/umngxuma luyimilinganiselo kwindlela yokulungelelanisa umzimba. .Umzimba kunye nepleyiti esezantsi yesixhobo iya kumakishwa rhoqo nge-100mm kwiindlela ze-X, Y kunye ne-Z.

Umyili wesixhobo olungileyo kufuneka akwazi ukushwankathela nokuqonda.Ukwenza isifaniso, kungakhathaliseki ukuba i-bracket yokulinganisa okanye isixhobo sokulinganisa esincinci, kwinqanaba elithile, i-design yabo yesakhiwo ifana ne-calligraphy yaseTshayina.I-calligraphy yaseTshayina ibeka ingqalelo kwilaphu elimhlophe, ubukhulu obufanelekileyo, ukusabalalisa kakuhle, ukulinganisa, ukulinganisa kwesobunxele nasekunene, ukulungelelanisa ngokubanzi, ubuhle bonke.Oku kufuneka kube njalo xa kuyilwa i-fixture.automotive parts kwimveliso, iqinisekisa ukhuseleko kunye nesantya sokulungiswa kwendibano yeemoto, kwaye iphucula umgangatho wamacandelo eemoto.

Ukuqukuqela kokuSebenza

1. Ifumene iodolo yokuthenga-——->2. Uyilo-——->3. Ukuqinisekisa umzobo/izisombululo-——->4. Lungisa izixhobo-——->5. CNC-——->6. CMM-——->6. Ukudibanisa-——->7. CMM-> 8. Ukuhlolwa-——->9. (uhlolo lwecandelo le-3 ukuba kuyimfuneko)-——->10. (ngaphakathi/umthengi kwisiza)-——->11. Ukupakisha(ibhokisi yomthi)-——->12. Ukuhanjiswa

Ukunyamezela ukuVeliswa

1. I-Flatness ye-Base Plate 0.05/1000

2. Ukutyeba kweBase Plate ±0.05mm

3. IDatamu yendawo ±0.02mm

4. Umphezulu ±0.1mm

5. Izikhonkwane zokuHlola kunye neMingxunya ± 0.05mm

.png)

.png)