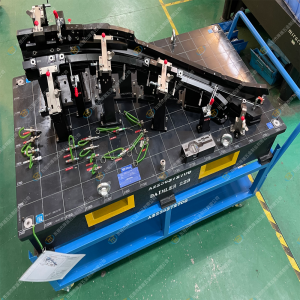

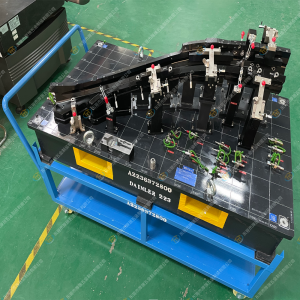

Ukuhlolwa kweFom yiGo/No-Go Gages Roof Frame ekhohlo Intsika enye yentsimbi yokuJonga iFixture

Ividiyo

Iinkcukacha ezibalulekileyo

| Uhlobo lokuLungisa: | Uphawu / CMM Combo Fixture |

| Igama leNdawo: | Isakhelo sophahla sishiye intsika LH&RH |

| Ilizwe elithumela ngaphandle: | Jemani |

| Ubuninzi: | Iiseti ezi-2 kwiTotali |

| Izinto: | Isinyithi |

Ngathi

Intshayelelo

Isixhobo sisetyenziselwa ukujonga ukuba ubungakanani, imilo, indawo kunye nezinye iiparameters ze-A-intsika kwicala lasekhohlo lesakhelo sophahla lwemoto iyahlangabezana neemfuno zoyilo.Inokunceda abavelisi baphucule ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso, kunye nokunciphisa iingozi zemveliso kunye neengxaki zekhwalithi ezibangelwa yi-A-pillar dimensions engahambelani neemfuno.

Uyilo kunye nokuveliswa kweSakhelo sophahla esiKhohlo iNtsika yokuHlola iFixture kufuneka ithathele ingqalelo iimodeli ezahlukeneyo zeemoto, ngoko ke iqhele ukwenziwa ngokwezifiso.Ngexesha lenkqubo yokuvelisa, kuyimfuneko ukuyila kunye nokusebenza ngokwemizobo yomzekelo kunye neemfuno zokuvavanya ezinikezelwa ngumthengi.Kwangaxeshanye, ukwenziwa kohlolo lwe-TTM kufuneka kulawulwe ngokungqongqo ngokuhambelana nenkqubo yolawulo lwekhwalithi ye-ISO9001 ukuqinisekisa ukuchaneka kunye nokuzinza kolu luhlu.

Ukuqukuqela kwethu kokuSebenza

1. Ifumene iodolo yokuthenga-——->2. Uyilo-——->3. Ukuqinisekisa umzobo/izisombululo-——->4. Lungisa izixhobo-——->5. CNC-——->6. CMM-——->6. Ukudibanisa-——->7. CMM-> 8. Ukuhlolwa-——->9. (uhlolo lwecandelo le-3 ukuba kukho imfuneko)-——->10. (ngaphakathi/umthengi kwisiza)-——->11. Ukupakisha(ibhokisi yomthi)-——->12. Ukuhanjiswa

Ukunyamezela ukuVeliswa

1. I-Flatness ye-Base Plate 0.05/1000

2. Ukutyeba kweBase Plate ±0.05mm

3. IDatamu yendawo ±0.02mm

4. Umphezulu ±0.1mm

5. Izikhonkwane zokuHlola kunye neMingxunya ± 0.05mm

.png)

.png)