TTMyinkampani esekwe kakuhle enxulumene nemoto ephumelele inqanaba eliphezulu lokuzisebenzela.Sisebenza ngokukhethekileyo kwimveliso yeemotoizixhobo zokuhlola, izixhobo zokuwelda, kwayeukungunda.Kweli nqaku, singathanda ukwazisa impembelelo yomgangatho wamandla kwimveliso yeemoto.

Itekhnoloji kunye nenqanaba le-automation yeshishini lokuvelisa iimoto liya linyuka kwaye liphezulu, kwaye inani elikhulu leempembelelo kunye nemithwalo engahambelaniyo isetyenziswa kwiinkqubo zayo eziphambili zokuvelisa, ezinje ngoomatshini bokuwelda bombane kunye noomatshini bokuwelda i-laser kwivenkile yomzimba, oomatshini besitampu ngaphakathi. ivenkile yokupakisha, kunye nezixhobo zokuguqulela rhoqo kwivenkile yepeyinti., umgca wokuvelisa ngokuzenzekelayo kwi-workshop yendibano, njl., le mithwalo inento eqhelekileyo, oko kukuthi, ukuguquguquka komthwalo kukhulu kakhulu kwaye isizukulwana se-harmonic sikhulu kakhulu.Ngexesha elifanayo, kunye neemfuno eziqhubekayo zelizwe ukunciphisa ukusetyenziswa kunye nokugcina amandla, inani elikhulu lezibane zokulondoloza amandla zisetyenziswa;iinjini zemveli ngokuthe ngcembe zithatyathelwa indawo zidrive zokuguqula amaza.Le mithwalo emitsha ingeyomda yenza mandundu ukuwohloka komgangatho wamandla kushishino lokwenziwa kweemoto.

Iingxaki zamandla zangoku

Ngohlalutyo lweenkcukacha-manani lovavanyo lomgangatho wamandla, kufumaniseke ukuba ezona ngxaki ziphambili zomgangatho wamandla kushishino lokwenziwa kweemoto zii-harmonics, ukuguquguquka kwamandla ombane kunye neengxaki zamandla asebenzayo, ezikho ngokubanzi kumakhonkco ohlukeneyo anje ngestamping, ukuwelda, ukupeyinta, i-powertrain kunye neyokugqibela. indibano.

1. Iworkshop yokunyathela - i-harmonics, ukuguquguquka kwamandla ombane kunye ne-flicker

Imithwalo ebuthathaka kwiworkshop yokugximfizwa igxile kakhulu koomatshini bokushicilela, kubandakanywa iirobhothi kunye nombane we-DC.Uninzi lokushicilela luqhutywa yi-DC speed-adjustable motors kwaye lufuna unikezelo lombane oluzinzileyo lweDC.Iinjini zerobhothi zilawulwa yi-PLC kwaye ziqhutywa ngabaguquli befrikhwensi.Iisekethe zolawulo lwe-PLC kunye nabaguquli befrikhwensi zombini zingumthwalo oqhelekileyo obuthathaka.

2.Ivenkile yokupeyinta - i-harmonic

Ipeyinti yepeyinti yemoto ihlulwe ibe yimigangatho emine, i-primer, idyasi ephakathi, i-base coat kunye ne-varnish.Ngaphandle kokuba i-primer kufuneka ifakwe kwi-pool pool yebhetri, ezinye iinkqubo zifana ngokusisiseko.Iworkshop yokutshiza ngokuzenzekelayo yiworkshop yemveliso enekhonkco lenkqubo ephezulu.Ukusilela kwesixhobo ngasinye Kuya kuchaphazela yonke inkqubo yevenkile yokutshiza.

3.Uqeqesho lwamandla

I-powertrain ibhekisela ikakhulu kwimveliso ye-injini, kwaye impembelelo yamandla ombane igxininiswe kwizixhobo zomshini we-CNC kwi-workshop yomatshini, kunye nezixhobo zokuhambisa, imigca yendibano, kunye namaqonga okuvavanya.Izixhobo ezibizayo kunye nezixhobo eziyinkimbinkimbi zidinga ukusetha kwakhona iiparitha zoomatshini, ukuchithwa kwezinto zokusebenza, izixhobo eziyingozi, ukumisa imigca yokuvelisa, ukulinda umsebenzi, njl.

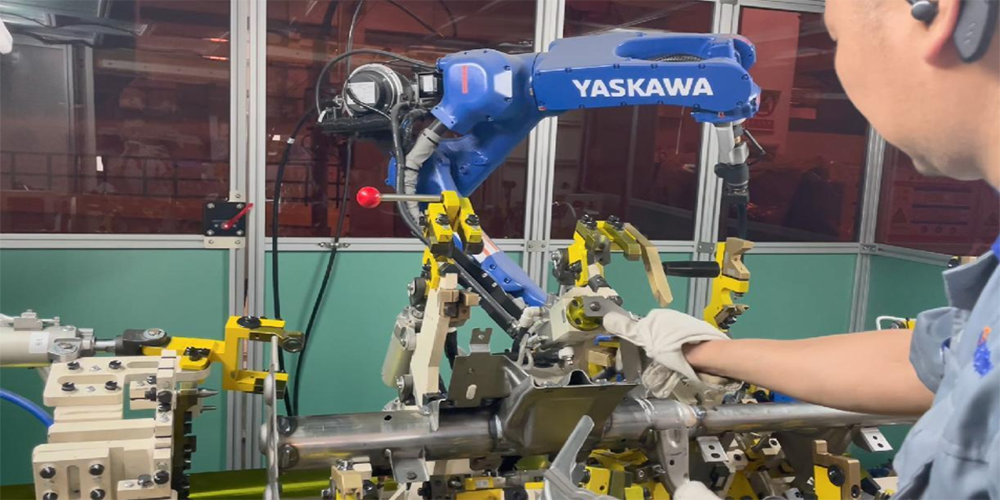

4.INdibano yokugqibela – Harmonics

Inkqubo yokugqibela yokuhlanganisa ikakhulu isebenzisa iirobhothi zokudityaniswa okuzenzekelayo, kunye nenani elikhulu lamacandelo e-elektroniki anje ngeediode, ii-triodes, imisinga ekhuselweyo, iibhulorho zokulungisa, kunye nokuhanjiswa kwamandla asetyenziswa kwiisekethe eziqhuba iirobhothi.I-superposition yenani elikhulu le-harmonics ayiyi kuchaphazela kakhulu inkqubo yokubonelela umbane, kodwa kwakhona Kuyingozi ukulimaza ubomi kunye nokusebenza ngokuchanekileyo kwerobhothi.

Ixesha lokuposa: May-17-2023

.png)

.png)