Ijigi idla ngokuqulunqwa yinto yokubeka (ukuchonga indawo echanekileyo yesixhobo sokusebenza kumdlalo), isixhobo sokulungisa, isixhobo esikhokelayo somsiki (ukumisela indawo ehambelanayo yomsiki kunye nomsebenzi okanye isikhokelo somsiki), isixhobo sokwahlula i-workpiece inokugqiba ukucutshungulwa kwezikhululo ezininzi kwiifakelo ezimbini, kubandakanywa i-rotary kunye ne-linear ehambayo yokwahlula i-device), i-element edibeneyo kunye ne-fixture body (isiseko sokulungiswa), njl. njalo njalo, yeyiphi i-jig yomatshini eqhelekileyo, ehlala ifinyeziwe njenge-jig.Xa kusetyenzwa i-workpieces kwisixhobo somatshini.Ukuze wenze umphezulu we-workpiece uhlangabezane neemfuno zobugcisa zemilinganiselo, iimilo zejometri kunye nokuchaneka kweendawo ezihambelanayo zeminye imiphezulu echazwe kwimizobo, i-workpiece kufuneka ilungiswe, ibekwe kwaye ixinzelelwe ngaphambi kokuba iqhutywe.

Iindidi zeJig zinokwahlulwa zibe:① ijig yendalo yonke.Efana ne-vise yomatshini, i-chuck, i-sucker, intloko eyahlulayo kunye netafile ejikelezayo, njl., zinendawo yonke enkulu.Ulwakhiwo lwayo luye lwabunjwa, imilinganiselo yalo kunye neenkcukacha zenziwe nge-serialized, uninzi lwazo ziye zaba yinto eqhelekileyo yezixhobo zomatshini.② I-jig ekhethekileyo.Yenzelwe ngokukodwa kwaye yenzelwe iimfuno zokubethelwa kwenxalenye yemveliso kwinkqubo ethile.Injongo yenkonzo yodwa kwaye ijolise kakhulu.Ngokubanzi, iyilwe ngumvelisi. Ngokuqhelekileyo, bandakanya ijig yelathe, ijig yomatshini wokugaya, i-drilling die (isixhobo somatshini ijig yokukhokela umsiki ukugrumba okanye imingxuma ephinda-phindayo kwisixhobo sokusebenza), ukufa okukruqulayo (isixhobo somatshini sejig sokukhokela isixhobo esikruqulayo. umngxuma kwisixhobo sokusebenza) kunye nokukhapha ijig (yesixhobo esiphathwayo kumgca ozenzekelayo wesixhobo somatshini esidityanisiweyo) ③ Ijigi ehlengahlengiswayo.Ijigi ekhethekileyo enokutshintshwa okanye ilungelelaniselwe amacandelo.④ Umdibaniso wejig.Jig eyenziwe ngamacandelo asemgangathweni weemilo ezahlukeneyo, iinkcukacha kunye ne-USES zifanelekile kwimveliso yovavanyo lweemveliso ezintsha kunye neengcezu zomntu ngamnye, ukuveliswa kwebhetshi encinci kunye nemisebenzi yesikhashana ehlala ithathelwa indawo yimveliso emitsha.Ukongezelela kwi-vice, i-chuck, intloko yokwahlula kunye netafile ejikelezayo, kukho kwakhona i-handle cutter eqhelekileyo.Ngokuqhelekileyo, xa igama elithi cutter kunye ne-jig livela ngexesha elifanayo, ininzi ye-jigs ibhekisela kwi-handle cutter.

lathi jig

Isixhobo se-jib esisetyenziselwa ukucubungula indawo yangaphakathi, yangaphandle kunye neendawo zokusebenza kwi-lathe ibizwa ngokuba yi-jig device ye-lathe.Ininzi ye-lathe jig ifakwe kwi-spindle, ezimbalwa zifakwe kwi-saddle yebhedi okanye umzimba webhedi.

Umatshini wokulinganisa oneendlela ezintathu

Isetyenziswe kumatshini wokulinganisa kunye nenkxaso yemodyuli, isixhobo sokubhekisela ekufezekiseni ukulungiswa okuguquguqukayo kwendawo yokusebenza phantsi kovavanyo.Isixhobo sinokucwangciswa ngokuzenzekelayo ukuxhasa i-workpiece kunye nokuseta amanqaku angenamkhawulo wokubhekisela kwi-workpiece configuration.I-software ekhethekileyo ekhethekileyo, inokuthi ngokuthe ngqo ngokusebenzisa idatha yejometri ye-workpiece, kwimizuzwana embalwa ukuvelisa inkqubo yokudibanisa i-workpiece.

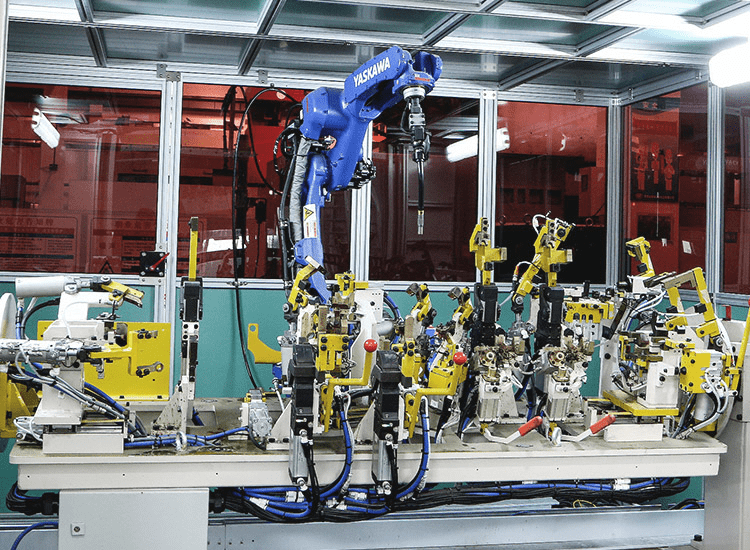

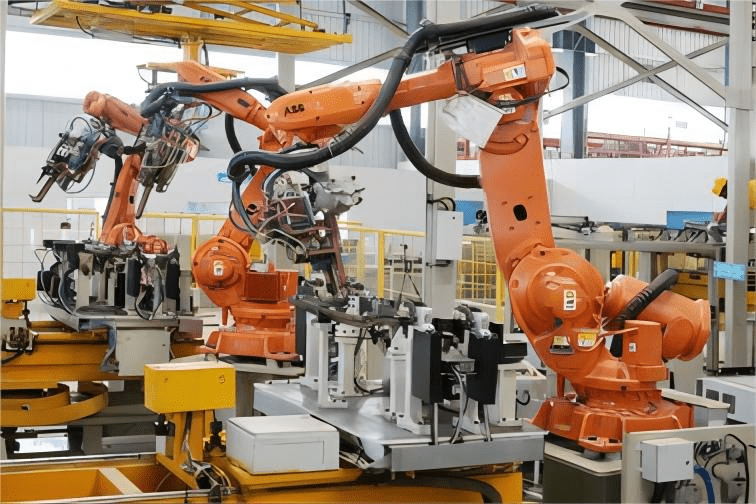

Ukulungiswa kweerobhothi kwimizi-mveliso

Zonke zifakwe kwiirobhothi zemizi-mveliso kwaye zisetyenziswa kwizixhobo ezizisebenzelayo kwimizi-mveliso, eyenye yetekhnoloji entsha yezixhobo zala maxesha zokuzenzela.Ukusetyenziswa okuqhelekileyo kukulayisha kunye nokulayisha izixhobo zoomatshini, ukupakisha i-workpiece, i-welding, ukugaya kunye nezinye iifektri ezizenzekelayo ezingenamntu.

I-jig yokugaya

Zonke zifakwe kwitafile yokusila, kunye nokunyakaza kwetafile yomatshini.Ikakhulu iqulunqwe isixhobo sokumisa, isixhobo sokudibanisa, isixhobo sokudibanisa ikhonkrithi, isixhobo sokudibanisa kunye ne-cutter.Kwinkqubo yokugaya, amandla okusika makhulu, kunye namandla okusika. i-intermittent kwaye i-vibration inkulu.Ngoko ke, amandla okubamba umatshini wokugaya mkhulu, kwaye ukuqina kunye namandla esixhobo se-jig siphezulu.

Ukuthwala i-pedestal jig

Ukuze kuqinisekiswe umgangatho wemveliso ye-bearing pedestal kunye nokuphucula umgangatho wemveliso ye-bearing pedestal, ukongeza ekusebenziseni izixhobo zoomatshini kunye nezinye izixhobo zoomatshini, kuya kusetyenziswa inani elikhulu lezixhobo zobuchwepheshe.Kubandakanya ukunyathela i-clamps, i-molds, iimela kunye Izixhobo ezincedisayo ezihambelanayo.Ukuthwala i-pedestal jig sisixhobo sokuvelisa esisetyenziselwa ngokukodwa ukuqinisekisa umgangatho wokuthwala iimveliso ze-pedestal.Inokwenza inkqubo yokuvelisa i-pedestal ibe lula ngakumbi.Izixhobo ezihlukeneyo zokuthwala i-pedestal ziya kuhluka ngokwezakhiwo zazo ezahlukeneyo kunye neefom, ukusebenza. Iimeko kunye nemigaqo yoyilo. Ke kukho iintlobo ezahlukeneyo kunye nezimbo zesibambi se-asi, zombini ngokobuninzi kunye nesimbo. iqiniswe, ukwenzela ukuba intshukumo efunekayo kwi-workpiece processing igqitywe.i-fixture of bearing pedestal idlala indima ebaluleke kakhulu kwinkqubo yokuvelisa, ngoko kubaluleke kakhulu ukuzoba umzobo woyilo lwe-fixture.

Ixesha lokuposa: Jan-06-2023

.png)

.png)